Introduction

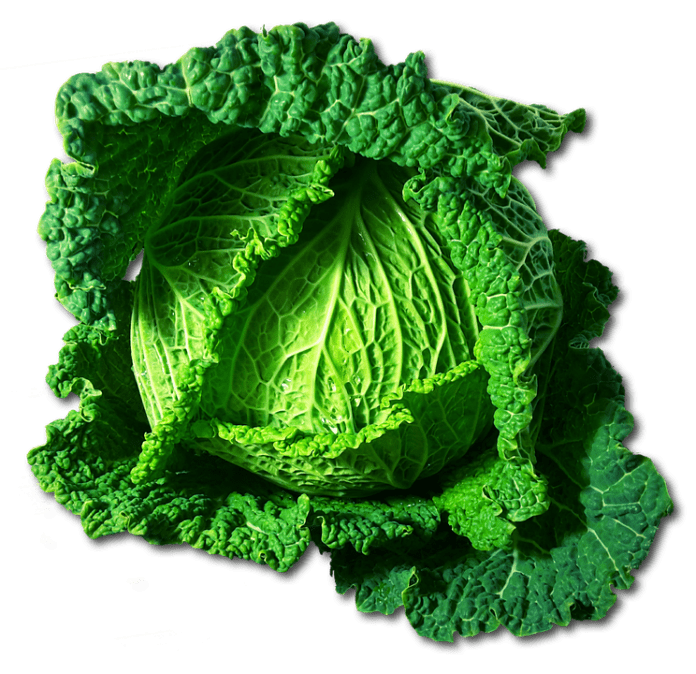

Waste reduction in cabbage processing is a critical issue that affects both the environment and the bottom line of businesses in the food industry. By finding innovative ways to turn byproducts into profits, companies can not only reduce their environmental impact but also increase their profitability. In this report, we will explore the various strategies and technologies that can be implemented to reduce waste in cabbage processing and maximize the value of byproducts.

The Problem of Waste in Cabbage Processing

Cabbage processing generates a significant amount of waste in the form of trimmings, peels, and other byproducts. According to a study by the Food and Agriculture Organization (FAO), as much as 30% of cabbage weight can end up as waste during processing. This waste not only contributes to environmental pollution but also represents a missed opportunity for businesses to generate additional revenue.

Current Practices in Waste Management

Many cabbage processing facilities currently dispose of their byproducts through landfilling or incineration, which can be costly and environmentally damaging. Some companies may also sell their byproducts to animal feed producers at a low price, but this often does not fully recoup the costs of processing.

Opportunities for Waste Reduction

There are several opportunities for waste reduction in cabbage processing that can help businesses minimize their environmental impact and increase profitability. One approach is to implement more efficient processing techniques that produce less waste. For example, using advanced cutting and sorting technologies can help minimize trimmings and other byproducts.

Turning Byproducts Into Profits

One of the most effective ways to reduce waste in cabbage processing is to find ways to turn byproducts into profitable products. By extracting value from these byproducts, companies can offset the costs of processing and potentially generate additional revenue streams.

Value-Added Products

One strategy for turning cabbage byproducts into profits is to create value-added products that can be sold to consumers. For example, cabbage peels can be used to make vegetable stock or soup bases, which can be packaged and sold in retail stores. By adding value to these byproducts, companies can tap into new markets and increase their profitability.

Animal Feed and Fertilizer

Another option for utilizing cabbage byproducts is to sell them as animal feed or fertilizer. Cabbage trimmings can be dried and processed into animal feed pellets, which can be sold to livestock farmers. Similarly, cabbage waste can be composted and turned into organic fertilizer, which can be sold to agricultural producers.

Case Study: XYZ Cabbage Processing Company

XYZ Cabbage Processing Company is a leading producer of cabbage products in the region. The company has recently implemented a waste reduction program to turn its byproducts into profits. By partnering with a local animal feed producer, XYZ has been able to sell its cabbage trimmings at a premium price, generating additional revenue for the business.

Financial Impact

By selling its byproducts as animal feed, XYZ has been able to offset the costs of processing and increase its profitability. The company estimates that this initiative has resulted in a 20% increase in overall revenue, making it a significant success for the business.

Environmental Benefits

In addition to the financial benefits, XYZ’s waste reduction program has also had a positive impact on the environment. By diverting cabbage trimmings from landfilling, the company has reduced its carbon footprint and minimized its environmental impact. This has not only improved XYZ’s sustainability credentials but has also resonated with environmentally conscious consumers.

Conclusion

Waste reduction in cabbage processing is a critical issue that businesses in the food industry must address. By finding innovative ways to turn byproducts into profits, companies can not only reduce their environmental impact but also increase their profitability. Strategies such as creating value-added products, selling byproducts as animal feed, and partnering with other businesses can help businesses maximize the value of their byproducts and contribute to a more sustainable food industry.