A University at Buffalo-led research team has secured a $3 million grant from the US Department of Energy to develop innovative membrane technology aimed at reducing the energy consumption required in the production of food, chemicals, and other products. This breakthrough has the potential to lower production costs and decrease greenhouse gas emissions, ultimately making everyday goods more affordable and environmentally friendly.

The principal investigator of the grant, Miao Yu, who serves as the SUNY Empire Innovation Professor in the Department of Chemical and Biological Engineering at the School of Engineering and Applied Sciences, outlined the primary goal of the project. The team aims to create cost-effective membranes that are resistant to solvents and heat, capable of withstanding the harsh conditions present in industrial processes used to manufacture various products.

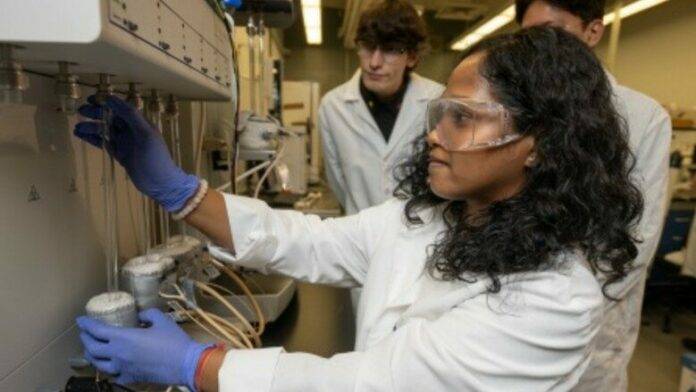

Collaborating with students and three companies – GTI Energy, Marquis Energy, and Media and Process Technology Inc. – Yu and his team are working towards developing membranes made of titanium oxide and carbon. These new membranes are designed to be more durable than conventional plastic membranes, allowing them to be utilized in industrial separation processes without degradation.

The focus of the research project is on soybean oil processing, a common industrial procedure that currently involves energy-intensive methods such as distillation and crystallization. By implementing the new membrane technology, the team hopes to eliminate the need for heating the soybean oil to remove impurities, potentially reducing energy consumption by up to 70%.

The membranes being developed are 50 to 80 centimeters in length and can be arranged into modules. Researchers have the ability to customize the size and shape of nanopores in the membranes, enabling the passage of molecules of different sizes. Additionally, these membranes are capable of withstanding temperatures of up to 250 degrees Celsius, making them suitable for a wide range of industrial applications.

Through extensive testing, the team plans to demonstrate the viability of the new membrane technology by processing crude soybean oil continuously for 500 hours, equivalent to approximately three weeks. If successful, this technology could revolutionize the industry by offering a more efficient and environmentally friendly alternative to traditional production methods.

The potential applications of this membrane technology extend beyond soybean oil processing, with implications for various industries such as chemicals and pharmaceuticals. UB’s Technology Transfer office has already initiated the patenting process for this technology, and efforts are underway to commercialize it for widespread use.

The funding for this project comes from the Energy Department’s Industrial Efficiency and Decarbonization Office, as part of a larger initiative to support innovative projects aimed at reducing energy consumption and greenhouse gas emissions in industrial processes. This project is one of 16 initiatives awarded a total of $38 million in funding, highlighting the significance of the research being conducted by the University at Buffalo-led team.

In conclusion, the development of this membrane technology represents a significant step towards achieving more sustainable and cost-effective industrial processes. By reducing energy consumption and greenhouse gas emissions, this innovation has the potential to make a positive impact on both the economy and the environment.