The Logistics of Fruit Crisps Distribution and Global Trade Networks

Introduction

Fruit crisps have become a popular and healthy snack option for consumers around the world. The process of distributing fruit crisps involves a complex logistics network that ensures the product reaches its destination in a timely and efficient manner. In this report, we will explore the logistics of fruit crisps distribution and how global trade networks play a crucial role in the supply chain.

Overview of the Fruit Crisps Industry

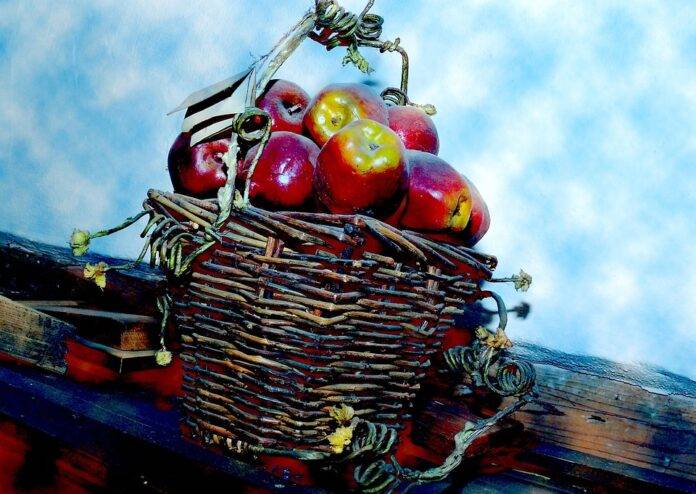

The fruit crisps industry has experienced significant growth in recent years, driven by increasing consumer demand for healthy and convenient snack options. Companies in this industry produce fruit crisps by dehydrating or freeze-drying various fruits to preserve their nutrients and flavors. Popular fruit options for crisps include apples, bananas, strawberries, and mangoes.

Key Players in the Fruit Crisps Market

Several key players dominate the fruit crisps market, including companies like Bare Snacks, FruitziO, and Crunchies Natural Food Company. These companies use different distribution channels to reach consumers, such as supermarkets, convenience stores, online retailers, and specialty health food stores.

Logistics of Fruit Crisps Distribution

The logistics of fruit crisps distribution involve multiple steps that ensure the product is delivered from the manufacturer to the end consumer. These steps include sourcing raw materials, production, packaging, storage, transportation, and retail distribution. Efficient logistics management is essential to minimize costs, reduce lead times, and meet customer demand.

Sourcing Raw Materials

The first step in the distribution of fruit crisps is sourcing raw materials, such as fresh fruits. Companies work with fruit suppliers to ensure a consistent and high-quality supply of fruits for production. The sourcing process involves negotiating prices, quality checks, and establishing long-term relationships with suppliers to secure a steady source of raw materials.

Production and Packaging

Once the raw materials are sourced, the fruits are processed through dehydration or freeze-drying techniques to create fruit crisps. The production process involves cutting, slicing, drying, and packaging the fruit crisps into convenient snack-sized portions. Companies invest in state-of-the-art equipment and technology to ensure the quality and consistency of their products.

Storage and Transportation

After production, fruit crisps are stored in warehouses before being transported to distribution centers or directly to retailers. Proper storage conditions, such as temperature and humidity control, are critical to preserve the freshness and quality of the product. Transportation methods vary depending on the distance and destination, with options including trucks, trains, ships, and air freight.

Retail Distribution

Retail distribution of fruit crisps involves delivering the product to various sales channels, such as supermarkets, convenience stores, and online retailers. Companies work with distributors and wholesalers to reach a wide range of customers and expand their market reach. Effective retail distribution strategies include product placement, promotions, and marketing campaigns to drive sales.

Global Trade Networks and Market Trends

Global trade networks play a significant role in the distribution of fruit crisps, as companies rely on international markets for sourcing raw materials and expanding their customer base. Trade agreements, tariffs, and regulations impact the flow of goods across borders and influence supply chain decisions. Market trends, such as the growing demand for organic and non-GMO products, also shape the fruit crisps industry.

Financial Data and Industry Insights

The fruit crisps industry is a multi-billion-dollar market, with steady growth expected in the coming years. Companies invest in research and development to innovate new flavors, packaging designs, and production techniques to stay competitive in the market. Consumer preferences for healthy and natural snacks drive demand for fruit crisps, leading to increased sales and market share for industry players.

In conclusion, the logistics of fruit crisps distribution involve a complex network of processes that ensure the product reaches consumers efficiently and on time. Global trade networks play a crucial role in sourcing raw materials and expanding market reach for companies in the fruit crisps industry. By understanding these logistics and market trends, companies can optimize their supply chain and meet the growing demand for healthy snack options worldwide.