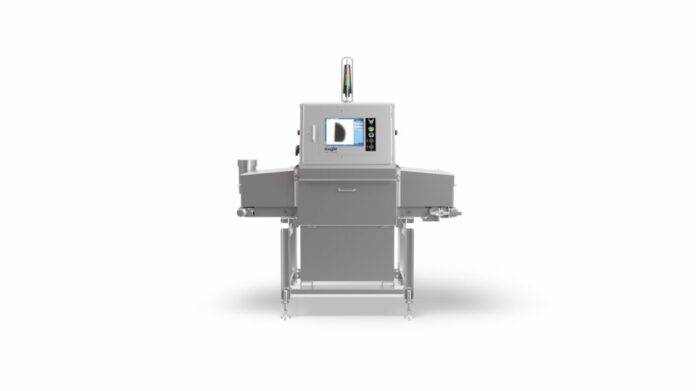

In the dairy manufacturing industry, ensuring product safety and quality is essential to meet stringent regulations and continuous improvement goals. To address these challenges, Eagle has developed the Pack 400, an advanced x-ray inspection system designed specifically for the dairy industry. This system is built to meet hygienic standards and provides contaminant detection and quality assurance.

The Pack 400 HC is ideal for harsh washdown environments commonly found in dairy facilities. It can inspect dairy products packaged in various types of containers, such as plastic containers, cartons, boxes, and pouches. The system is capable of identifying and rejecting contaminants like glass shards, dense plastic and rubber pieces, metal fragments, and mineral stones. In addition to contaminant detection, the Pack 400 HC also performs essential quality checks, including fill-level verification, mass measurement, and package integrity assessments, such as cap or closure placement for drinkable yogurts. It can even identify voids within products, ensuring consistency and quality, such as blocks of cheese.

Christy Draus, head of marketing for Eagle Product Inspection, explains, “The Pack 400 HC can detect everything from foreign materials to structural issues like broken cheese slices or seal integrity problems that could lead to spoilage.” Beyond food safety, the system can also help prevent product giveaway by providing highly accurate weight measurements, allowing manufacturers to identify under-filling or overfilling issues and leading to significant cost savings for dairy manufacturers.

The Pack 400 HC is designed for easy and effective sanitation, with features like welded stainless-steel plates, tool-less belt removal, interlocked hinged louvers, and a specially designed cabinet that deflects water. This ensures durability in dairy washdown environments. The system meets NAMI sanitary design standards, has an IP69 Ingress Protection rating, and is built for quick changeovers and long-term reliability, capable of running up to two shifts a day, seven days a week.

To further enhance operational efficiencies, Eagle offers advanced PXT photon-counting, dual-energy x-ray technology, paired with Eagle’s SimulTask PRO for a “dynamic duo” capability that enhances inspection results by combining advanced image processing with a touchscreen interface. As processors comply with traceability requirements, they can also add Eagle’s TraceServer technology for network-based data and image storage and transfer.

For more information about Eagle’s Pack 400 HC or other inspection solutions for dairy facilities, visit their website at https://www.eaglepi.com/products/x-ray-machines/pack-400-hc/.

In conclusion, Eagle’s Pack 400 HC is a cutting-edge x-ray inspection system that addresses the unique challenges faced by dairy manufacturers. It provides advanced contaminant detection, quality assurance, and operational efficiencies, all while meeting stringent hygiene standards and ensuring product safety and quality in the dairy industry.