Introduction

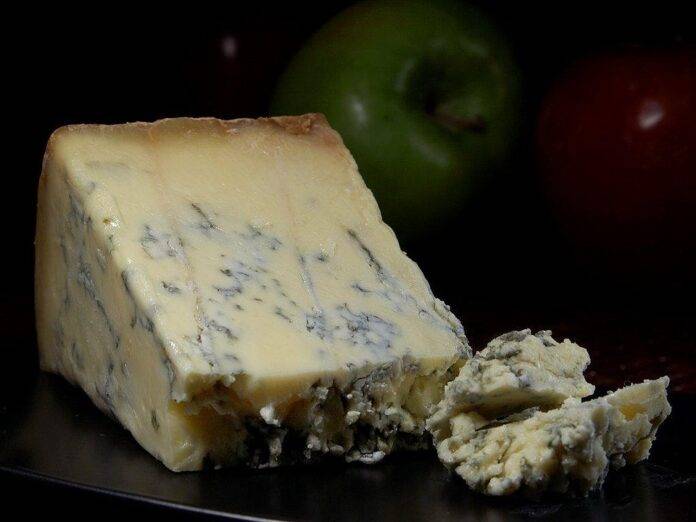

Blue cheese is a popular type of cheese known for its distinct blue mold veins and tangy flavor. Properly packaging, storing, and distributing blue cheese is crucial to maintain its quality and extend its shelf life. In this report, we will discuss the best practices for packaging, storing, and distributing blue cheese to ensure its freshness and flavor are preserved.

Packaging Blue Cheese

Blue cheese is typically sold in wedge or crumbled form. When packaging blue cheese, it is important to use materials that allow for proper airflow while also protecting the cheese from external contaminants. Vacuum-sealed packaging is commonly used for blue cheese as it helps preserve the cheese’s moisture content and prevents mold growth.

Materials

Packaging materials for blue cheese should be food-grade and resistant to moisture and oxygen. Common materials used for packaging blue cheese include plastic wrap, foil, and vacuum-sealed bags. It is important to ensure that the packaging materials are clean and free from any contaminants that could affect the quality of the cheese.

Labeling

Proper labeling is essential when packaging blue cheese. Labels should include important information such as the type of cheese, expiration date, storage instructions, and any allergen information. Clear and accurate labeling helps consumers make informed decisions about the product and ensures compliance with food safety regulations.

Storing Blue Cheese

Blue cheese should be stored in a cool, dark, and humid environment to prevent it from drying out or developing off-flavors. Proper storage conditions are essential to maintaining the quality and flavor of blue cheese over time.

Temperature

Blue cheese should be stored at a temperature between 35-45°F (1-7°C). Temperatures that are too cold can cause the cheese to become too hard, while temperatures that are too warm can promote mold growth and spoilage. It is important to store blue cheese in the refrigerator away from other strong-smelling foods to prevent flavor absorption.

Humidity

Blue cheese should be stored in a humid environment to prevent it from drying out. The ideal humidity level for storing blue cheese is around 80-90%. This can be achieved by placing the cheese in a container with a humidifier or by storing it in a cheese cave or cellar.

Distributing Blue Cheese

Proper distribution of blue cheese is crucial to ensure that it reaches consumers in optimal condition. Distributors play a key role in maintaining the quality and integrity of blue cheese throughout the supply chain.

Transportation

When transporting blue cheese, it is important to use temperature-controlled vehicles to prevent the cheese from spoiling. Blue cheese should be packed and handled carefully to avoid damage during transit. Distributors should work closely with suppliers to ensure that proper packaging and handling procedures are followed to maintain the quality of the cheese.

Storage at Retailers

Once blue cheese reaches retailers, it should be stored in a cool environment to maintain its freshness. Retailers should follow proper storage guidelines to ensure that the cheese is not exposed to temperature fluctuations or contaminants that could affect its quality. Proper rotation of stock is also important to prevent spoilage and ensure that consumers are purchasing fresh blue cheese.

Conclusion

Proper packaging, storing, and distributing blue cheese is essential to maintain its quality and flavor. By following best practices for packaging, storing, and distributing blue cheese, producers, distributors, and retailers can ensure that consumers enjoy a high-quality product that meets their expectations. Remember, proper handling and storage are key to preserving the unique taste and texture of blue cheese.