Denhay Farms, a UK-based bacon producer, has recently implemented Ravenwood’s linerless technology to fully automate its packaging operations. This strategic move has not only resulted in a reduction in labor but has also significantly improved production line efficiency. The linerless sleeves used by Denhay Farms closely resemble traditional hand-applied sleeves but are supplied on a roll, making them easier to use and more efficient.

To facilitate this transition, Denhay Farms has installed two Ravenwood Nobac 5000 linerless applicators. Additionally, the company has partnered with UK-based linerless printer, ProPrint Group, to produce the linerless sleeves. Jim Loescher, Managing Director of Denhay Farms, expressed his satisfaction with the integration of the linerless applicators and sleeves into their production process, noting the transformation of their labeling operations into a faster and more efficient process. He highlighted the premium quality of the linerless sleeves, which align perfectly with Denhay’s brand image.

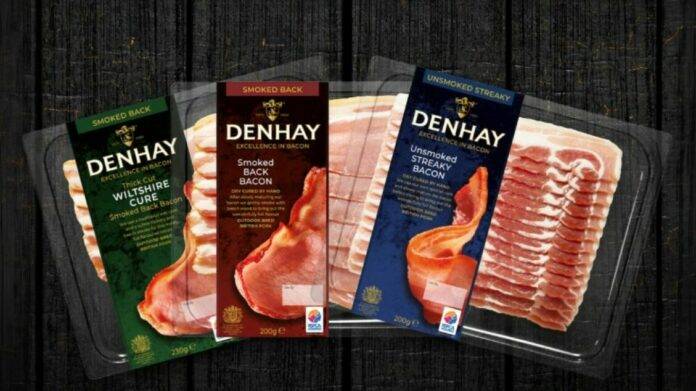

The decision to switch to linerless technology is part of Denhay’s broader efforts to reduce manpower on the packaging line, enhance staff welfare, and maximize value through smarter spending. By transitioning from labor-intensive hand sleeving to fully automated labeling, Denhay has been able to streamline its operations across all its own-label sliced bacon products, including the Spoilt Pig brand and wholesale catering packs.

The Ravenwood Nobac 5000 linerless applicators have the capability to sleeve a variety of pack formats and tray sizes, offering flexibility for Denhay’s diverse product range. The transition to linerless has not only improved efficiency but has also led to a reduction in storage and shipping space, thanks to the compact nature of linerless reels.

Prior to adopting linerless technology, Denhay employees were engaged in repetitive manual sleeving tasks. With the switch to linerless, staff can now focus on more valuable tasks, leading to improved overall operations and a boost in morale. Jim Loescher emphasized the importance of staff well-being in Denhay’s operations and noted the positive impact of the transition to linerless technology on employee satisfaction.

Throughout the transition, Denhay Farms was committed to maintaining the premium look and feel of their original cardboard sleeves. Ravenwood’s linerless sleeves, designed to meet aesthetic standards and supplied on a roll, have proven to be a sustainable and eco-friendly solution. During initial trials, concerns were raised about visible white lines in the plate repeat pattern on the linerless sleeves. ProPrint Group addressed this issue by filling the join with the same Pantone color as the sleeve border during the artwork stage, ensuring a premium appearance at no additional cost to the customer.

Founded in 1952, Denhay Farms has a long-standing reputation for producing high-quality bacon products. Their products are available through Tier 1 and Tier 2 retailers, as well as online platforms such as Ocado and Amazon Fresh. With the successful integration of Ravenwood’s linerless technology, Denhay Farms is poised to further enhance its production processes and expand the use of linerless technology across its product range.

In conclusion, Denhay Farms’ adoption of Ravenwood’s linerless technology represents a significant step towards automation and efficiency in packaging operations. The successful implementation of linerless sleeves has not only improved productivity and reduced labor costs but has also enhanced staff morale and overall operational effectiveness. Denhay Farms’ commitment to sustainability and premium quality is evident in their choice of linerless technology, which offers a sleek and eco-friendly packaging solution. As Denhay Farms continues to grow and evolve, the use of linerless technology is expected to play a key role in driving further innovation and success in the company’s bacon production.