Cost and Maintenance Comparisons for Plough and Harrow Equipment

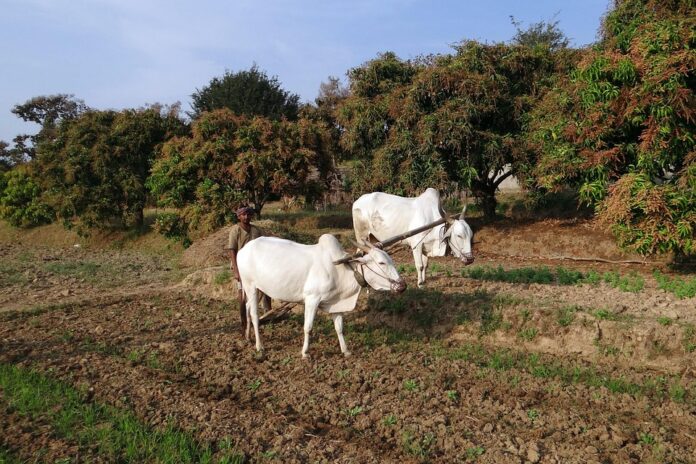

Plough and harrow equipment are essential tools used in agriculture for tilling and preparing the soil for planting crops. Farmers often face the dilemma of choosing between these two types of equipment based on their cost and maintenance requirements. In this report, we will compare the costs and maintenance considerations for ploughs and harrows to help farmers make informed decisions.

Cost Analysis

When it comes to purchasing agricultural equipment, cost is a significant factor that farmers need to consider. Ploughs and harrows vary in terms of initial purchase price, operational costs, and long-term expenses. Let’s delve into the cost comparison between ploughs and harrows.

Initial Purchase Price: Ploughs typically have a higher initial purchase price compared to harrows. This is due to the complexity and size of plough equipment, which requires more materials and technology to manufacture. On the other hand, harrows tend to be simpler in design and are generally more affordable for farmers looking to invest in soil preparation equipment.

Operational Costs: In terms of operational costs, ploughs may require more maintenance and replacement parts compared to harrows. Ploughs have more moving parts and are subjected to higher levels of wear and tear due to the nature of their function. This results in higher maintenance costs over the lifespan of the equipment.

Long-Term Expenses: When considering long-term expenses, ploughs may have a higher total cost of ownership compared to harrows. Factors such as fuel consumption, repair and maintenance costs, and depreciation should be taken into account when calculating the overall expenses of using ploughs versus harrows.

Maintenance Considerations

Maintenance is a crucial aspect of owning agricultural equipment, as regular upkeep ensures optimal performance and longevity of the machinery. Let’s explore the maintenance considerations for ploughs and harrows to help farmers make informed decisions.

Plough Maintenance: Ploughs require regular maintenance to ensure that they function properly and efficiently. This includes greasing moving parts, checking for wear and tear, and replacing worn-out components. Additionally, ploughs need to be properly cleaned and stored to prevent corrosion and damage.

Harrow Maintenance: Harrows are generally easier to maintain compared to ploughs due to their simpler design and fewer moving parts. Regular inspection, cleaning, and lubrication are essential for keeping harrows in good working condition. Harrows are also less prone to mechanical failures, reducing the need for frequent repairs and replacements.

Cost of Maintenance: The cost of maintenance for ploughs and harrows can vary depending on factors such as the brand, age, and usage of the equipment. In general, ploughs may have higher maintenance costs compared to harrows due to their more complex nature and higher susceptibility to wear and tear.

Industry Insights

In the agricultural industry, the choice between ploughs and harrows often depends on factors such as the type of soil, crop rotation practices, and budget constraints. Farmers need to weigh the cost and maintenance considerations of each type of equipment to determine the most suitable option for their farming operations.

Financial Data: According to industry reports, the global market for agricultural equipment is projected to reach $166 billion by 2025. This growth is driven by increasing mechanization in agriculture and the adoption of advanced technologies in farming practices.

Actual Companies: Leading manufacturers of ploughs and harrows include John Deere, Case IH, and AGCO Corporation. These companies offer a range of agricultural equipment options to meet the diverse needs of farmers worldwide.

In conclusion, the cost and maintenance considerations for plough and harrow equipment play a significant role in determining the most suitable option for farmers. While ploughs may have a higher initial purchase price and maintenance costs, they are essential for deep tillage and soil turning. On the other hand, harrows are more affordable and easier to maintain, making them ideal for surface-level soil preparation. Farmers should carefully evaluate their farming needs and budget constraints to choose the right equipment that will enhance their agricultural operations.