Introduction

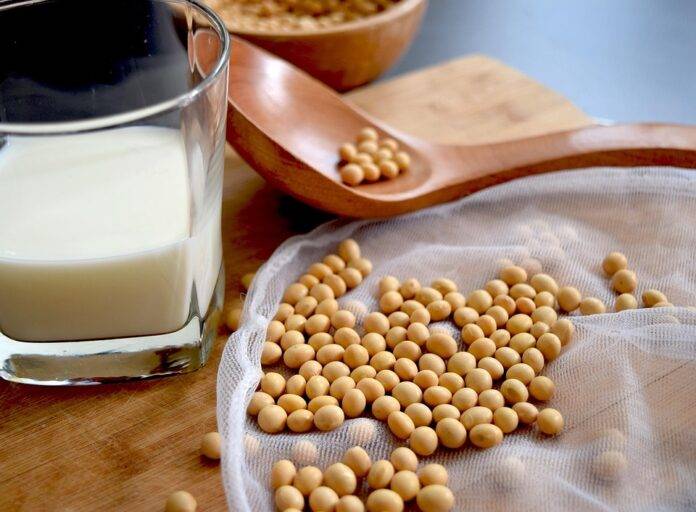

Soy milk has gained popularity in recent years due to its health benefits and suitability for individuals with lactose intolerance or dairy allergies. As the demand for plant-based milk alternatives continues to rise, it is essential for manufacturers to implement effective cold chain and shelf stable distribution strategies to ensure the quality and safety of their products. In this report, we will explore the key considerations and best practices for distributing soy milk in both cold chain and shelf stable conditions.

Cold Chain Distribution Strategies

Importance of Cold Chain

Cold chain distribution is crucial for perishable products like soy milk, as it helps maintain the product’s quality, freshness, and safety throughout the supply chain. By keeping soy milk at a consistent temperature range, typically between 2-4 degrees Celsius, manufacturers can prevent bacterial growth and extend the product’s shelf life.

Transportation

When transporting soy milk in a cold chain, manufacturers must use refrigerated trucks or containers to maintain the required temperature. It is essential to work with reliable logistics partners who have experience in handling temperature-sensitive products to minimize the risk of spoilage or contamination during transit.

Storage

Once soy milk reaches its destination, proper storage facilities are essential to ensure product quality. Cold storage warehouses with temperature-controlled environments are ideal for storing soy milk before it is distributed to retailers or consumers. Regular monitoring of temperature levels and adherence to food safety regulations are critical in maintaining the integrity of the product.

Challenges

Despite the benefits of cold chain distribution, there are challenges that manufacturers may face, such as high transportation costs, the need for specialized equipment, and the risk of temperature fluctuations during transit. However, investing in a robust cold chain infrastructure can help mitigate these challenges and ensure the consistent quality of soy milk products.

Shelf Stable Distribution Strategies

Overview

Shelf stable distribution involves packaging soy milk in a way that allows it to be stored at room temperature for an extended period without the need for refrigeration. This method provides convenience for consumers and reduces transportation and storage costs for manufacturers.

Packaging

To achieve shelf stability, soy milk is typically packaged in aseptic containers that prevent contamination and spoilage. These containers are sterilized before filling to eliminate bacteria and other microorganisms that could cause the product to spoil. Aseptic packaging also helps extend the product’s shelf life without the need for preservatives.

Distribution Channels

Shelf stable soy milk can be distributed through various channels, including supermarkets, convenience stores, and online retailers. Manufacturers can leverage these channels to reach a broader consumer base and increase the availability of their products in different regions. It is essential to partner with distributors and retailers who have experience in handling shelf stable products to ensure proper storage and display.

Advantages

Shelf stable distribution offers several advantages for manufacturers, including reduced transportation costs, longer shelf life, and increased flexibility in distribution. By eliminating the need for refrigeration, manufacturers can expand their market reach and cater to consumers in areas where cold chain infrastructure may be limited.

Industry Insights

Market Trends

The global soy milk market is experiencing steady growth due to increasing consumer awareness of the health benefits of plant-based alternatives. According to market research reports, the market is projected to reach a value of $XX billion by 2025, with a compound annual growth rate of X%. This growth presents opportunities for manufacturers to expand their product offerings and explore new distribution strategies to meet consumer demand.

Key Players

Several major players in the soy milk industry have implemented effective cold chain and shelf stable distribution strategies to maintain product quality and meet consumer expectations. Companies such as Silk, Alpro, and Oatly have established strong distribution networks and innovative packaging solutions to ensure the availability of their products in various markets worldwide. By investing in technology and infrastructure, these companies have successfully navigated the challenges of distributing soy milk in both cold chain and shelf stable conditions.

Future Outlook

As consumer preferences shift towards plant-based products, the demand for soy milk is expected to continue growing in the coming years. Manufacturers will need to adapt to changing market dynamics and consumer preferences by implementing efficient distribution strategies that prioritize product quality and safety. By leveraging technology, data analytics, and strategic partnerships, companies can optimize their supply chain operations and enhance the overall customer experience.

In conclusion, effective cold chain and shelf stable distribution strategies are essential for ensuring the quality, safety, and availability of soy milk products in the market. By implementing best practices and investing in infrastructure, manufacturers can meet consumer demand, expand their market reach, and capitalize on the growing popularity of plant-based milk alternatives.