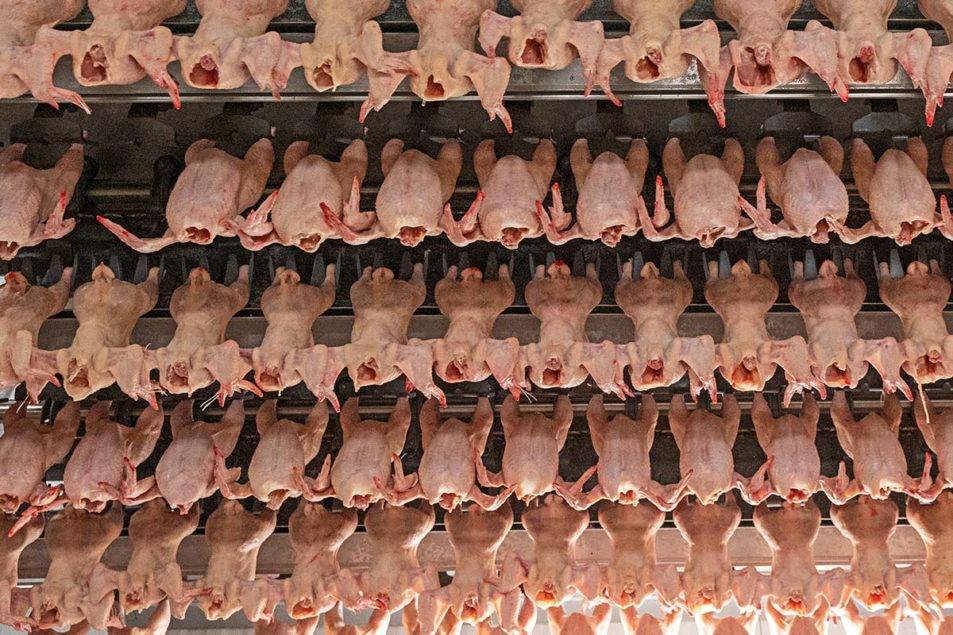

In recent years, the poultry processing industry has seen a shift towards air-chilled technology as the preferred method for cooling poultry post-slaughter. This trend is driven by the need for more efficient and environmentally friendly chilling methods. Traditional methods, such as water chilling, often involve refrigerated tank chilling, which consumes a significant amount of water. In contrast, air chilling reduces water consumption, addressing environmental concerns in many regions.

Historically, the US poultry industry favored water chilling due to its positive impact on yield, while air-chilling presented yield challenges that made processors hesitant to adopt the technology. However, this reluctance is changing as air-chilled chicken gains popularity for its distinct taste and texture. Unlike water-chilled chicken, air-chilled chicken locks in flavor and retains moisture, making it a more appealing option for consumers.

Randy Wilson, industry sales manager for poultry at Marel, an Iceland-based company with US offices in Lenexa, Kan., explained that air chilling uses a controlled air circulation system to cool the birds, offering several benefits for food safety, quality, and efficiency. Processors using air-chilled technology produce a higher quality meat product with flavor and moisture locked into the meat. This is particularly popular in regions where consumers and fast-food chains prefer air-chilled products for their superior flavor and texture.

Another advantage of air-chilled technology is that it leads to more accurate product labeling. The birds retain their true weight without the added water that often accompanies traditional methods, fostering transparency for consumers and helping processors manage pricing more effectively.

The growing demand for air-chilled poultry has led to numerous innovations by manufacturers, with more intelligent drive systems and advanced refrigeration control systems that improve efficiency. For example, the Baader Clean Air Chill System features a one-level air chilling process before the birds enter a multi-level maturation room. This system maximizes airflow to ensure the highest quality of air-chilled chicken, preserving its taste and texture.

Marel has installed 25 air-chilled lines at plants around North America and 350 in 60 other countries worldwide. The company offers three types of air-chilled systems, each uniquely designed based on the weight of the birds. These systems include the Downflow Plus, InfraChill, and Shock Masteration Chill, each offering different advantages in terms of chilling efficiency and product quality.

As the poultry industry continues to seek ways to deliver the highest quality products to consumers, air-chilled systems are expected to become even more important. Ongoing advancements in air chilling technology will ensure that it remains a key consideration for processors looking to improve both efficiency and product quality in the future.