Cold Chain Storage and Transport of Emmental Cheese

Emmental cheese, also known as Swiss cheese, is a popular type of cheese characterized by its distinctive holes and nutty flavor. In order to maintain its quality and freshness, proper cold chain storage and transport are essential. This report will delve into the intricacies of cold chain logistics for Emmental cheese, including the processes involved, key players in the industry, and the financial implications of ensuring proper storage and transportation.

The Importance of Cold Chain Storage

Cold chain storage refers to the uninterrupted series of refrigerated production, storage, and distribution activities that ensure perishable products like Emmental cheese are kept at the optimal temperature at all times. Maintaining the cold chain is crucial for preserving the quality, safety, and shelf life of the cheese. Any break in the cold chain can lead to spoilage, contamination, and a loss of product quality.

The Process of Cold Chain Logistics

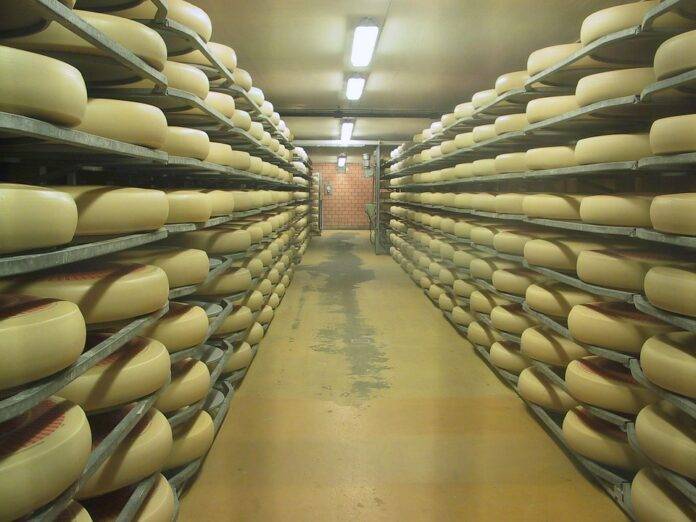

The cold chain process for Emmental cheese begins at the production facility where the cheese is aged and packaged. Once the cheese is ready for distribution, it is transported in refrigerated trucks or containers to storage facilities or distribution centers. These facilities are equipped with temperature-controlled environments to ensure that the cheese remains at the appropriate temperature throughout the storage period.

From the storage facility, the cheese is then transported to retailers or consumers in refrigerated vehicles to maintain the cold chain. It is crucial that the cheese is stored and transported at the correct temperature to prevent spoilage and maintain its quality. Monitoring systems are often used to track the temperature of the cheese throughout the entire cold chain process.

Key Players in the Cold Chain Industry

Several companies play a significant role in the cold chain storage and transport of Emmental cheese. Refrigerated transport companies such as Carrier Transicold, Thermo King, and Daikin Reefer are responsible for providing temperature-controlled vehicles for the transportation of perishable goods, including cheese.

Storage facilities like Lineage Logistics and Americold also play a crucial role in maintaining the cold chain for Emmental cheese. These facilities offer temperature-controlled storage solutions to ensure that the cheese is kept at the right temperature until it reaches its final destination.

Financial Implications of Cold Chain Logistics

Ensuring proper cold chain storage and transport for Emmental cheese comes with significant financial implications. The cost of refrigerated vehicles, storage facilities, monitoring systems, and trained personnel can add up quickly. However, the consequences of not maintaining the cold chain can be even more costly, as it can lead to product spoilage, recalls, and damage to the brand reputation.

According to industry data, the global cold chain market is projected to reach $447.50 billion by 2025, driven by the increasing demand for temperature-controlled storage and transport of perishable goods like cheese. This growth presents opportunities for companies involved in cold chain logistics to expand their services and reach new markets.

In conclusion, cold chain storage and transport are essential components of ensuring the quality and safety of Emmental cheese. By understanding the processes involved, key players in the industry, and the financial implications of maintaining the cold chain, companies can better navigate the complex logistics of storing and transporting perishable goods like cheese.