The last ten years have seen a significant rise in two opposing diet trends: poultry meat and plant-based meat alternatives. This surge in popularity presents new and diverse inspection challenges for food manufacturers looking to increase and expand production to meet consumer demands.

Consumers are increasingly prioritizing “healthy eating,” opting for high-protein, low-fat, nutrient-rich products over overly-processed foods. Many are seeking to reduce their intake of processed foods, sugar, fat, salt, and, in some cases, red meat. In the United States, health and sustainability are also key considerations for mindful food choices, according to a McKinsey Insights report on conscious eating.

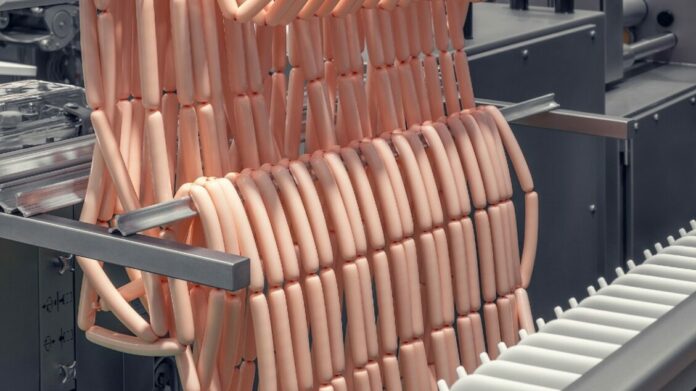

The popularity of leaner meats, particularly chicken, has soared in the past decade. At the same time, the meat-alternatives market is growing rapidly, with major meat conglomerates investing in plant-based protein lines. As food manufacturers experience a surge in demand for new product applications, it is crucial for them to review their current Critical Control Points (CCPs) and safety controls as their facilities expand and production lines diversify.

Protein-rich options, such as poultry, are in high demand. USDA statistics show that poultry is the most consumed livestock commodity globally, with the average individual in the U.S. consuming over 100 lbs. of chicken meat annually. Fitness and diet culture have played a significant role in driving the demand for poultry products, as research suggests that a diet rich in high-quality, lean protein can help prevent obesity and build muscle mass. Chicken has become the preferred meat option in America due to its high protein-per-gram ratio and cost-effectiveness compared to red meat.

The trend of protein-fortified foods, fueled by the bodybuilding world and social media, has led to an abundance of products with added protein on supermarket shelves. With 79 million global vegans seeking meat and dairy substitutes with higher protein content, the market for plant-based meat alternatives is booming. Sales of plant-based meat surged 42% between March 2016 and March 2019, reaching $888 million.

The global protein market is projected to double from $10.37 billion in 2022 to around $23.34 billion by 2032. This growth in the meat and meat-alternative market means that more products are passing through individual facilities, increasing the risk of recalls and food safety threats. As new equipment, processes, and production lines are introduced, additional control measures are needed to ensure food safety.

In the U.S., chicken breast remains the most popular cut, attributed to its versatility and low fat content. As poultry processors increase their stock of chicken breast, the risk of physical contaminants during production, such as metal, also rises. Regular food safety audits are essential to prevent issues like poor record-keeping and non-compliance, which can lead to audit failures.

Strategic selection of high-contaminant-risk checkpoints and inspection equipment on protein processing lines can help prevent contamination. When introducing new processes or packaging, risk professionals should revisit inspection protocols and hypothetical contamination scenarios to identify potential gaps in the value chain. Proper education and training of staff on standardized testing procedures for inspection equipment can help manage food safety hazards effectively.

Processors with fast-growing operations often implement multiple Critical Control Points (CCPs) to target food safety hazards. By including both upstream and end-of-line metal detection, one protein processor reduced costs associated with good product waste, time, and labor by 50%. Collaboration with inspection system providers can help identify the best system for the application, maximizing benefits like saving floor space, cutting costs, and enhancing process efficiency.

While plant-based burger patties and sausages are currently popular vegetarian and vegan options, trends in consumer preferences can change rapidly. It is crucial for processors to remain vigilant in identifying hazards and Critical Control Points, regardless of the size or speed of their production line expansion. Adapting to these evolving consumer demands and ensuring food safety are essential for food manufacturers in today’s market.