sizes=”(max-width: 600px) 100vw, 600px” alt=”” title=”nord”/>

NORD’s specialized solutions for the poultry and meat processing industry are highly reliable, cost-effective, and built to withstand harsh wash-down environments.

NORD DRIVESYSTEMS is set to participate in the upcoming International Production & Processing Expo (IPPE), recognized as the world’s largest annual event focused on the poultry and meat processing industries. This year, the expo will take place at the Georgia World Congress Center in Atlanta, GA, from January 28 to 30, 2025. NORD boasts a modular product system featuring over 20 million standard configurations, enabling tailored solutions that meet specific application needs without the necessity for expensive custom components. Their offerings for poultry and meat processing encompass hygienic gear motors with smooth surfaces, versatile electronic motors, intelligent variable frequency drives, and ready-to-install overhead conveyor drives, among others.

Explore NORD’s Solutions at Booth B38075

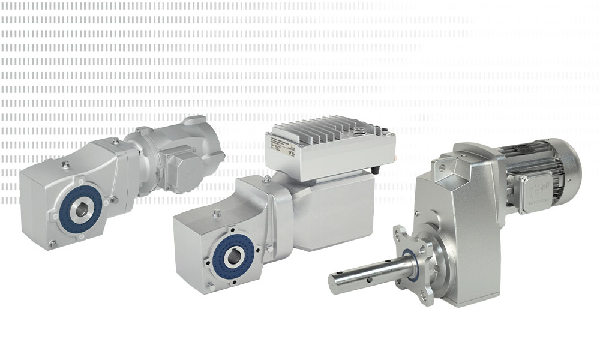

Smooth Surface Gear Units and Motors

NORD employs a high-strength, lightweight aluminum alloy for its smooth surface gear units and motors, delivering exceptional thermal conductivity and inherent corrosion resistance. The smooth surface UNICASE™ gear units provide a hygienic, durable design that encloses all gear components and bearing points, facilitating easy cleaning and resilience in demanding wash-down scenarios. The available gear units include NORDBLOC.1® helical inline gear units, NORDBLOC.1® helical bevel 93.1 series gear units, UNIVERSAL SMI worm gear units, and the DuoDrive integrated gear unit and motor. Furthermore, NORD’s smooth surface motors can be paired with any of their gear units, featuring protection options such as potted terminal boxes, condensation drain holes, and moisture-resistant varnish-dipped windings to prevent moisture and debris ingress.

Overhead Conveyor Drives

The overhead conveyor drives are designed with high-quality components and heavy-duty construction, featuring an output mounting flange and shaft that adhere to industry-standard footprints for seamless drop-in replacements. These drives are engineered with the standard VL3 spread bearing design, equipped with an oil-safe dry cavity that effectively absorbs high overhung and thrust loads, thereby extending bearing life and reducing maintenance requirements. An optimized oil leakage protection system, including QUADRILIP™ seals and an optional oil proximity sensor, safeguards the internal gearing. Additionally, H1 low- and high-temperature food-grade lubricants are available to endure the rigorous hygienic demands typical in food processing environments.

Screw Conveyor Package

NORD’s Screw Conveyor Package provides a compact and cost-effective drive solution compatible with UNICASE parallel shaft gear units and UNICASE helical bevel gear units. The design integrates closely stepped ratios with a direct motor or NEMA C-face input adapter, eliminating the need for top motor mounts, pulleys, belts, or guards. This streamlined approach minimizes excess parts, simplifies system maintenance, and enhances reliability, durability, and superior drive performance, ensuring greater direct torque transfer. The package also includes a QUADRILIP sealing system, standard CEMA flange and shaft assembly, and versatile mounting options with multiple bolt patterns.

IE5+ Synchronous Motors

The IE5+ synchronous motors from NORD leverage permanent magnet technology to provide consistent torque and high efficiency across a broad speed range, even under partial loads and low speeds. The non-ventilated variant (TENV) features a compact, hygienic design with smooth surfaces, ensuring high corrosion resistance and ease of cleaning. When part of a complete gear unit, these motors can achieve an IP69K rating, offering enhanced protection against moisture and chemicals. Their high efficiency contributes to lower operational and maintenance costs while reducing the number of system variants required.

DuoDrive Integrated Gear Unit and Motor

The DuoDrive integrated gear unit and motor unites the high efficiency of IE5+ synchronous motors with a single-stage helical gear unit in a compact, smooth surface housing. This design optimizes installation and space utilization while offering full Plug-and-Play capabilities for rapid commissioning and minimal downtime during servicing or replacement. With system efficiencies reaching up to 92%, the DuoDrive significantly reduces Total Cost of Ownership (TCO) and accelerates Return on Investment (ROI). Additional features include high power density and quiet operation, available with IP69K ingress protection for added durability.

NORDAC ON/ON+

The NORDAC ON/ON+ variable frequency drives are meticulously designed to cater to the specific requirements of horizontal conveyor technology. This product line includes a version compatible with IE3 asynchronous motors (NORDAC ON) and one optimized for IE5+ synchronous motors (NORDAC ON+). Characterized by an integrated multi-protocol Ethernet interface, full pluggability for swift commissioning, and dynamic PLC functionality for drive-related operations, these drives provide a compact and cost-effective solution for Industrial Internet of Things (IIoT) environments.